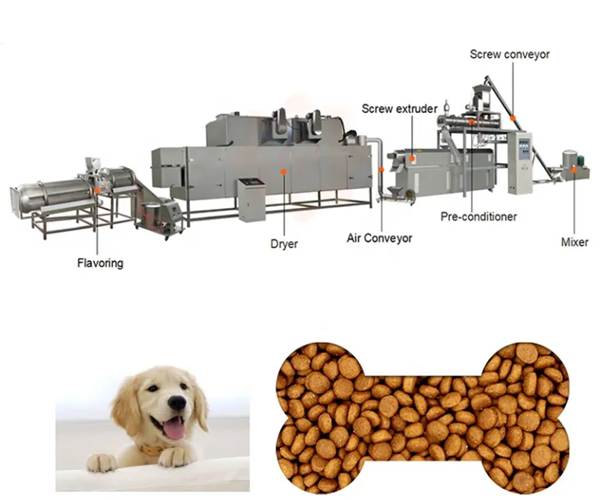

With the rapid growth of the pet market, more and more pet owners pay attention to the nutrition and safety of pet food. Foodline’s pet food production line can meet your needs well. It processes various raw materials into nutritious and balanced pet food through automated processes. The production line is suitable for a variety of products such as cat food, dog food, ornamental fish food, etc. Pet Food Production Line provides strong guarantees in food safety, efficiency and product consistency. If you are interested, please contact me. Phone: 86 13838385752

Equipment Parameter

| Type | Output | Size | Power |

| Feeding and mixing machine | 300kg | 1700*760*1820 | 7kw |

| Screw feeder | / | 6000*350*5800 | 2.2kw |

| Modulator | / | 1723*260*800 | 3kw |

| Steam generator | / | 720*470*1100 | 36kw |

| Large twin-screw puffing machine | 400-600KG | / | 75KW |

| Vibrating screen | / | 1.3*0.8*0.9m | 0.25kw |

| Air conveyor | / | 1.5*0.5*2.3m | 3KW |

| Eight meters seven layers electric drying oven | 400-700kg | 8.3*1.3*2.1 | 96kw |

| Fully automatic seasoning line | / | 3.1*0.9*1.8 | 3.5kw |

| Cooling air bed | / | 5*0.9*0.6 | 0.55kw |

Why Choose A Pet Food Production Line?

Choosing an efficient and stable Pet Food Production Line can bring many advantages, especially in terms of increasing production and ensuring food quality:

- High degree of automation: There are many automated equipment, which reduces manual intervention and improves production efficiency.

- Food safety assurance: The processing process is closed.It meets food-grade hygiene standards.

- Product quality assurance: Stable ratio and process ensure the consistent quality of each batch of pet food.

- Cost saving: Reduce labor costs and material waste.

- Multiple choices: Products are produced according to the food requirements of different animals.

Features Of Pet Food Production Line

- Strong adaptability: Machine supports a variety of raw materials and adapts to different formulas. The powder mixer in the production line integrates stirring and mixing functions to ensure that the raw materials are fully and evenly mixed. The high-speed motor drives the stirring wings to achieve efficient mixing, which is suitable for the processing needs of various materials such as powder and granules in the food industry.

- Easy to clean and maintain: The equipment material is corrosion-resistant and the structure is easy to clean, reducing the risk of contamination. The electric oven in this production line consists of an oven body and an intelligent control cabinet, with a compact structure and small footprint. It has a large drying area, low heat dissipation, and high thermal efficiency, which can effectively improve production efficiency.

- Energy consumption optimization: The equipment adopts inverter speed regulation technology to reduce energy consumption. The twin-screw extruder in the production line consists of seven core systems: modulation system, feeding system, extrusion system, peeling system, heating system, transmission system and intelligent control system. The main machine adopts variable frequency speed regulation technology.

Production Process Of Pet Food Equipment

The specific process of pet food is as follows:

- Raw material preparation: Prepare raw materials such as protein, carbohydrates, fats, minerals, etc. according to the recipe.

- Mixing: Use a powder mixer to mix the raw materials evenly to form a mixture suitable for extrusion.

- Extrusion: The core equipment, the twin-screw extruder, matures and expands the material through high temperature and high pressure.

- Vibration screening: The vibrating screen removes unqualified particles and screens out products of uniform size.

- Pneumatic conveying: The air conveyor transfers the particles to the next process section with high efficiency and no pollution.

- Drying: Use a drying box, electric oven or gas oven to dry the product to remove moisture and extend the shelf life.

- Seasoning: Use an oil sprayer and a seasoning machine to spray oil on the granules to enhance the taste and nutrition.

- Cooling conveyor: The cooling conveyor cools the food to room temperature for easy packaging.

Main Equipment In The Pet Food Production Line

The entire production line consists of several key equipment, among which the core equipment includes:

- Twin-screw extruder: Controlling the degree of expansion, density and shape is the core guarantee of product quality.

- Drying equipment: Electric oven, gas oven, drying box: Wide range of applications.They can be used to dry puffed foods or other materials in strips, blocks, granules, etc.

- Auxiliary equipment: Mixer, mix the initial raw materials;screw feeder: automatic feeding, connecting the mixing and puffing process; cutter: control the length of the particles; oil sprayer, evenly spray oil and seasoning powder; double roller/single roller, used for seasoning process.

FAQ

Yes. We can produce food according to the needs of different types of pets, supporting diversified products.

The equipment adopts an intelligent operation interface and is easy to operate. General workers can start work after simple training.

These equipment is made of 304 stainless steel. It is durable, easy to maintain and has stable operation.

Why Choose Foodline Machinery?

We are a large machinery company with 20 years of experience, able to deeply understand customer needs and quickly provide professional solutions. We have perfect after-sales service. We provide full-process technical support, including operation training and remote technical services, to ensure that customers have no worries. We have our own independent R&D team to continuously optimize equipment performance and energy consumption, keep up with the development trend of the pet food industry, and promote technological upgrades. If you are interested in this series of production lines, please contact us for more information.

Our company also provides vegetable cleaning machines, cotton candy vending machines and mobile food trailers.