In a rapidly evolving market, the search for precise and efficient filling equipment has become a common need across the food, pharmaceutical, and cosmetics industries. Servo filling machines are a representative example of filling equipment technology. With their high precision, intelligent functionality, and versatile applicability, they are becoming the preferred choice for companies looking to improve production capacity and quality.

If you’re looking for a filling machine that combines performance, stability, and ease of operation, this servo filling machine might be the right investment for you. Contact us for more information! WhatsApp/Phone: +86 13838385752.

Parameter of Filling Machine

| Specification | Details |

|---|---|

| Filling range | 50–5000ML (customized according to customer requirements) |

| Number of filling heads | 2, 4, 6, 8, 10, 12 |

| Filling speed | 10–35 (Bottle/min) (Take 8 heads of 500ml as an example) |

| Working pressure | 0.6–0.8MPA |

| Bin volume | About 20lb (Take 8 heads as an example) |

| Machine size | About 42847*52180 (length-width-height) |

| Machine weight | About 600KG |

| Measurement accuracy | ±1% (Depending on the specific material) |

| Power/voltage | 2KW/220V |

What is a Servo Filling Machine?

The servo filling machine is an intelligent filling device that utilizes a servo motor to control a piston or screw, precisely metering and dispensing liquids or highly fluid pastes. Its advantages lie in its high-precision control, adaptability to a wide range of viscosities, and automated integration into production lines. It is widely used in various industries, including food, pharmaceuticals, and cosmetics. This filling machine is suitable for core materials including low- to medium-viscosity liquids and fluid pastes. It achieves highly accurate quantitative filling, ensuring that every bottle meets quality standards.

Features of Filling Machine

Intelligent Touchscreen Operating System

The machine features a high-definition touch panel with a well-organized interface and clear operation steps, allowing quick operation without any technical background. It supports multi-language switching and operation permission settings, ensuring safe production and convenient operation.

High-Capacity Stainless Steel Hopper

The equipment is constructed of food-grade 304 stainless steel. Its sturdy and corrosion-resistant structure makes it particularly suitable for high-viscosity liquids and pastes. It can handle materials such as medical gels and thick sauces, ensuring high hygiene standards and a long service life.

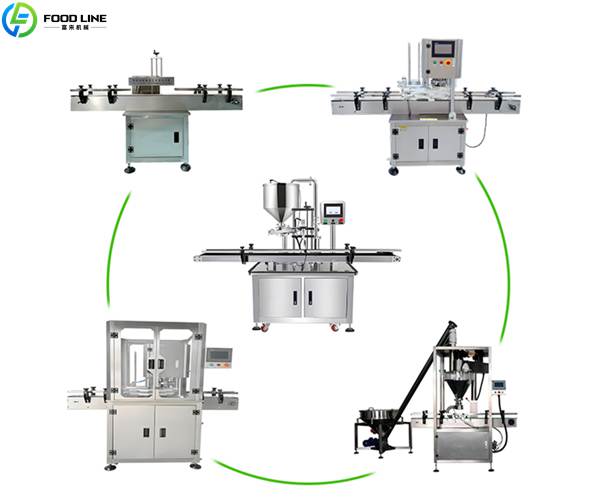

Automatic Conveying System

Equipped with a thick, wear-resistant conveyor belt, it automatically positions bottles for continuous filling, preventing tipping and bottle jams. It can handle multiple bottles for simultaneous filling, significantly improving production cycle times and making it ideal for high-load applications.

Universal Mobility and Secure Locking

The machine’s bottom is equipped with high-strength, lockable universal wheels for flexible positioning in the workshop. They can be locked with a single click, ensuring stable operation without shifting or shaking during production.

Modular Structural Design

The entire machine utilizes a modular design for ease of maintenance and upgrades. The number of filling heads, conveyor speed, and hopper capacity can be flexibly adjusted to meet production needs. This design accommodates production expansion at various stages.

Advantages of Servo Filling Machine

High Precision

Thanks to the servo system’s control, this servo filling machine produces virtually no waste during each filling process, making it particularly suitable for filling liquid products.

Strong Automation

It supports automatic bottle unscrambling, filling, and inspection functions, achieving optimal performance when used with assembly lines. This significantly reduces labor input and labor costs.

Stable and Durable

The entire machine is constructed of industrial-grade materials. Key components such as the filling head, conveyor belt, and hopper have undergone long-term load testing to ensure stable operation even in high-volume production.

High Hygiene

All liquid-contacting parts meet food and pharmaceutical industry standards. Acid and alkali resistant and easy to clean, they prevent cross-contamination and residue.

Applicable in Multiple Scenarios

Whether producing oils, seasonings, eye drops, or serums, this equipment can quickly switch between production modes. Its adaptability minimizes product line switching time and improves equipment utilization.

Wide Range of Applicable Products: Flexible Use in Multiple Industries

This servo filling machine is suitable for the following typical applications:

- Food Industry: Cooking oils, condiments, sauces, etc.

- Pharmaceutical Industry: Injectable solutions, eye drops, medical gels, etc.

- Cosmetics Industry: Preservatives, ampoules, light lotions, etc.

Due to its compatibility with materials of varying viscosities, this filling machine is an ideal choice for manufacturers across multiple industries and product lines.

Six Reasons to Choose Foodline Machinery: Quality and Service

- 20 years of industry experience: Dedicated to food machinery solutions, we maintain a global presence and are a trusted provider of solutions.

- Mastering core technologies: Our independently developed control system offers high precision, robust stability, and industry-leading filling error rates.

- Customized services: Provide one-stop filling line solutions tailored to industry, production volume, and bottle type requirements.

- International quality standards: Our equipment has passed multiple international quality certifications and is widely exported to countries in Europe, America, Southeast Asia, and beyond.

- Worry-free after-sales service: Provide online technical support and remote after-sales service, ensuring prompt response and thoughtful service.

- Continuous innovation and upgrading: Continuously optimize our servo system and intelligent recognition module to enhance user experience and automation levels.

Whether you’re a small, start-up factory or a large enterprise looking to upgrade, this filling machine can boost your production efficiency. Contact us now to start your automated filling upgrade! WhatsApp/Phone: +86 13838385752.