Sterilization is a key step in ensuring product safety and quality. As a processing device, the blanching machine uses hot water or steam as a medium to effectively sterilize, inhibit enzyme activity, and soften the material under controlled temperature and time. Welcome to contact us to learn more about this device. WhatsApp/Phone: +86 13838385752.

Blanching Machine Overview

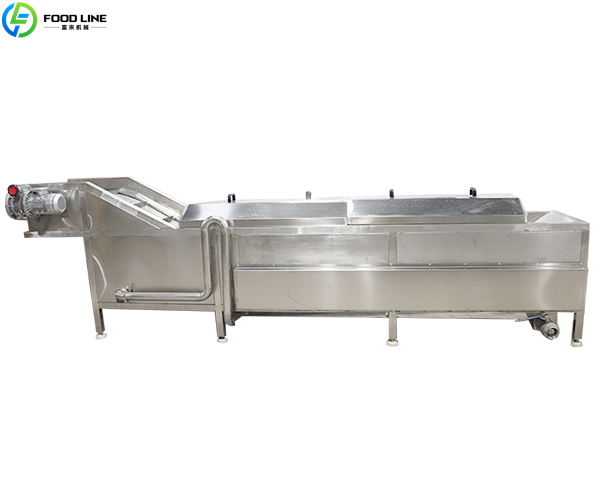

A blanching machine is a processing device designed based on the pasteurization principle and is widely used for blanching fruits and vegetables and sterilizing packaged products. This device uniformly heats the material with hot water or steam, effectively killing pathogens and bacteria within a specific temperature range. It also inhibits enzyme activity, extending the shelf life of food. The entire machine utilizes a stainless steel construction and supports stepless speed regulation and customizable temperature control.

Parameters of Vegetable Blanching Machine

| FL-B02 | Specification |

|---|---|

| Size | 7500×2300×2500 mm |

| Voltage | 380 V |

| Power | 6 KW |

| Output | 600-1000 kg/h |

Features of Blanching Equipment

Temperature Control System

The equipment features a built-in multi-zone temperature control system, ensuring uniform distribution of hot water or steam. Minimizing temperature differences prevents local overheating or underheating, ensuring product quality.

All-Stainless Steel Construction

Major contact areas are constructed of 304 stainless steel. It is corrosion-resistant, easy to clean, and meets food safety standards. It is suitable for high-humidity, high-frequency production environments.

Infinite Speed Regulation

The conveying system uses variable frequency speed regulation, allowing the conveyor speed to be adjusted according to the processing requirements of different materials. This allows for controlled heat treatment time and adaptability to various product processes.

Optional Heating Method

The vegetable blanching machine supports steam or hot water circulation heating, allowing users to choose their own energy source. It’s suitable for production lines requiring continuous steaming operations.

Customizable Design

It can be customized according to the user’s output, site, and product type.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Blanching Equipment

Sterilization and Enzyme Activity Control

Effectively kills bacteria, yeast, and other microorganisms, extending food shelf life.

Quality Assurance

Blanching improves the color of fruits and vegetables, removes unpleasant flavors, and softens the texture for subsequent processing.

Easy Operation

Adjustable parameters such as temperature and speed adapt to different product and process requirements.

High Operation Capacity

Suitable for automated production lines, achieving high-efficiency, large-scale processing.

Energy Saving and Environmental Protection

High thermal efficiency reduces overall energy consumption.

Applicable Product Range

Blanching machines are widely used in the processing of the following food materials:

- Vegetables

- Fruits

- Packaged meat products

- Aquatic products

FAQ

By strictly controlling the temperature and time, the blanching machine maximizes nutrient retention.

Steam heating heats up quickly and is suitable for materials that require high temperatures and short processing times. Hot water provides a more stable temperature and is suitable for products with dense textures or that require longer heating times. The choice depends on the product characteristics and your factory’s energy availability.

The equipment is highly automated, and basic operation requires minimal training.

Regularly drain the cleaning tank and clean any residue from the filter and conveyor belt. Regularly check the heating element and water pump operation.

Yes. The blanching machine can be used in conjunction with other equipment, including cleaning machines, cooling machines, and packaging machines.

Customer Success Stories

Case 1: American Vegetable Processing Plant

David Miller runs a medium-sized vegetable processing plant, primarily supplying supermarkets and frozen food companies. As order volume increased, he discovered that traditional hot water processing methods were inefficient. He decided to purchase our vegetable blanching machine. After using it, David commented:

“This equipment operates stably and is easy to operate, allowing us to blanch large quantities of vegetables in a short period of time. The vegetables retain their crispness and tenderness, improving product quality. Our factory’s production capacity has increased, and customer satisfaction has improved as well.”

Case 2: Vietnam Export Food Company

Nguyen Thi Hoa runs an export-oriented food company in Vietnam, primarily supplying frozen vegetables to the European market. Because exporting countries have very strict food hygiene and processing standards, she purchased our vegetable blanching machine.

Ms. Hoa shared, “The machine’s energy-saving design and automated features have significantly reduced our operating costs and made production more efficient.”

Why Choose Foodline Equipment

- Professional Capabilities: We have 20 years of experience in machinery R&D and manufacturing.

- Quality Assurance: All equipment is CE certified.

- One-Stop Service: We provide pre-sales, production, and after-sales support to ensure customers can use our machines smoothly.

- Export Experience: Our equipment has been exported to over 80 countries and regions.

Vegetable blanching machines are crucial equipment in food processing, directly impacting the quality of finished products. Choosing the right blanching machine is crucial to boosting your business. We also sell vegetable washing machines. Contact us for detailed information and a quote! WhatsApp/Phone: +86 13838385752.