Customer Purchase Overview

A US meat processing company decided to expand its production line. Founded by Mr. Michael Johnson, the company primarily supplies beef, pork, and poultry products to clients, including major supermarket chains and regional restaurant brands. As market orders increased, they discovered that traditional manual methods and outdated equipment were inefficient in processing meat products, resulting in inconsistent flavor.

After researching several suppliers, Mr. Johnson contacted us for detailed information on a commercial brine injector. Our team provided him with a comprehensive solution, including equipment specifications, capacity range, brine distribution uniformity, and maintenance methods. Mr. Johnson compared several models and watched videos demonstrating the performance of different models.

During the purchase process, he was concerned about three key aspects: uniform brine injection, ease of operation, stability, and after-sales service. After consultation and technical confirmation, Mr. Johnson ultimately selected two meat injector machines. After the equipment was delivered, installed, and commissioned, Mr. Johnson commented:

“This commercial brine injector injects brine evenly without damaging the meat. The installation process was also smooth. It has improved our production efficiency, reducing the processing time, which used to take several hours, by more than half.”

Overview of Saline Injection Machine

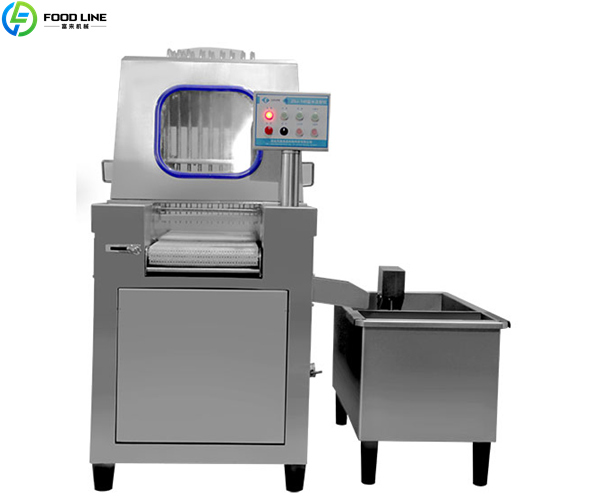

Commercial brine injectors are essential equipment in the modern meat processing industry. They use a high-pressure pump and precision needles to evenly inject brine, seasoning, or marinade into meat products. Compared to traditional brine methods, they shorten processing time and ensure uniform seasoning.

Whether used for beef, pork, or poultry, this equipment effectively improves product taste, tenderness, and moisture retention, providing consistent quality assurance for food processing plants.

Free Quote! WhatsApp/Tel: +86 13838385752.

Specifications of Brine Injector

| Parameter | Specification |

|---|---|

| Model | FL-120 |

| Injection Needles | 120 pcs |

| Production Capacity | 500-1500 kg/h |

| Motor Power | 1.5 kW (Variable Frequency) |

| Water Pump Power | 3 kW |

| Water Pump Pressure | 2 — 6.3 kg (adjustable) |

| Tank Width | 420 mm |

| Needle Vertical Stroke | 170 mm |

| Injection Speed | Variable Frequency Control |

| Chain Step Distance | 120 mm |

| Optional Needle Spec. | Ø304 mm |

| Host Machine Dimensions | 1350*1250*1720 mm |

| Feeder Cart Dimensions | 860*460*650 mm |

| Weight | 550kg |

Features of the Commercial Brine Injector

- Injection Technology: A multi-needle design ensures the brine or seasoning penetrates every part of the meat.

- Safety: The specially designed needles maintain injection efficiency while avoiding damaging the meat’s fiber structure.

- Control System: Adjustable injection pressure and speed for different meat types.

- Material: The equipment is constructed of stainless steel, meeting international food safety standards and easy to clean and maintain.

Advantages of Meat Brine Injector Machine

- Improved Efficiency: Shortens production time compared to traditional curing methods.

- Consistent Taste: Ensures consistent flavor from batch to batch, reducing quality fluctuations.

- Yield: Uniform injection ensures optimal moisture retention and weight of meat.

- Reduced Labor Costs: Highly automated equipment reduces manual intervention.

- Application: Suitable for meat of varying types and sizes, meeting diverse processing needs.

Suitable Products for Meat Brine Injection Machines

- Beef: steak, sirloin, frozen beef products.

- Pork: ham, bacon, pork chops.

- Poultry: chicken breast, turkey, duck.

- Processed meat: sausage, prepared seasoned meat products.

Why Choose Foodline Machinery

- Professional Experience: We have many years of experience manufacturing and exporting food processing equipment.

- Technical Support: We provide installation guidance, employee training, and long-term after-sales service.

- Quality Assurance: Our equipment is CE certified.

- High Cost-Effective: We offer quality at reasonable prices.

As the meat processing industry continues to pursue automation and quality, meat injector machines will become essential equipment in more and more processing plants. If you are interested, please contact us! WhatsApp/Phone: +86 13838385752.