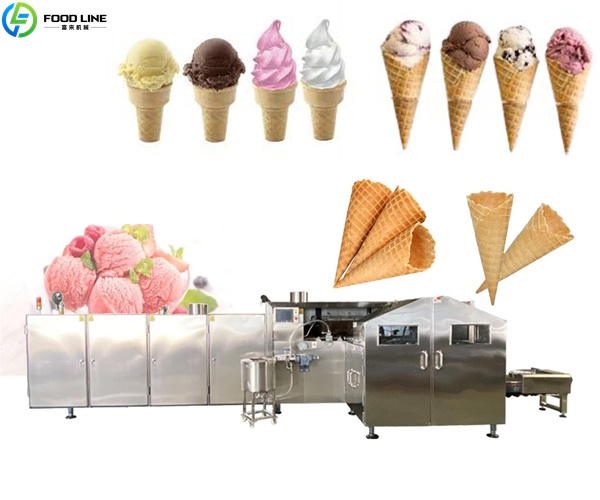

Italian Customers Purchasing Ice Cream Cone Production Line Overview

We recently supplied a fully automated ice cream cone production line to a client in Italy. This client is a well-established Italian ice cream producer specializing in a diverse range of flavors. To improve production efficiency and meet growing demand, they decided to invest in a cone production line.

This client had previously purchased other food machinery from us. This cone production line was part of their expansion efforts. According to their feedback, the most important factors they considered when selecting a supplier were equipment reliability, output, and the degree of automation. Purchasing Manager Giovanni Rossi stated, “When selecting the cone production line, we focused on equipment quality and after-sales service. We wanted to improve production efficiency while ensuring product quality.”

Ice Cream Cone Lines Overview

The cone production line is a fully automated system suitable for various production volumes and shapes. It can produce various shapes, including rounds, cones, crispy bowls, and cups, to meet diverse consumer needs. The production line includes several key equipment including mixers, forming machines, baking machines, cooling systems, automatic packaging machines, etc. All equipment is intelligently controlled, making it easy to operate and highly efficient.

Parameters of Ice Cream Cone Processing Line

Baking Equipment

| Model | Production Capacity (pcs/h) | Angle | Suitable for Cone Length | Baking Plate Size (MM) |

|---|---|---|---|---|

| FL117 x 2-40A | 10500~12000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL107 x 2-40A | 9500~11000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL85 x 2-36A | 7500~9000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL75 x 2-30A | 6500~8000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL53 x 2-20A | 4500~6000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL37 x 2-16A | 3000~4000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL159-24B | 4500-6000 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL139-24B | 4000-5500 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL107-24B | 3500-5000 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL71-20B | 2000-3500 | 14°-34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL61-16B | 1800-3000 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL45-16B | 1200-2200 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

Mixing and Conveying Equipment

| Equipment Type | Technical Parameter | Details |

|---|---|---|

| Mixer | Mixing Type | Turbine type |

| Device Configuration | Electrical control box, batter outlet (2 inch ball valve) | |

| Bottom Design | Tilting design for faster and adequate outflow | |

| Structure | Inner liner, insulation layer, protective shell | |

| Material | Stainless steel 304 | |

| Volume | 90L/190L/270L/320L | |

| Voltage | 220V/380V/415V/440V | |

| Rated Power | 3.0 KW/4.0 KW/5.5 KW | |

| Frequency | 50 HZ/60 HZ | |

| Batter Trolley | Device Configuration | Electrical control box, batter outlet (2 inch ball valve) |

| Bottom Design | Inclined type for better and faster batter flow | |

| Structure | Composed of a support frame and mixing barrel | |

| Material | Stainless steel 304 | |

| Volume | 280L |

Free Quote! WhatsApp/Tel: +86 13838385752.

Features of the Sugar Cone Production Line

Specifications

This production line not only produces standard cones, but can also adjust to produce other shapes.

Design

The equipment modules can be adjusted and upgraded to meet customer production needs. Customers can add or replace specific components of the production line as needed.

Temperature Control System

The production line is equipped with a precise temperature control system to prevent problems caused by temperature fluctuations.

Intelligent System

The production line’s control system utilizes PLC technology, enabling real-time monitoring of production status.

Advantages of Sugar Cone Processing Line

Automation

This production line features a high degree of automation, minimizing manual intervention.

Energy Saving

The production line is designed with energy efficiency in mind. Advanced heat recovery technology is used during the baking process to minimize energy consumption.

Production Capacity

Our ice cream cone lines can produce 1,200 to 12,000 cones per hour.

Product Quality

The shape, size, and firmness of the cones are highly consistent, ensuring that consumers receive quality products that meet quality standards.

Maintenance

The equipment is easy to operate, requiring minimal technical expertise. Maintenance is very convenient. Allow customers to perform routine maintenance themselves.

About Foodline Equipment

- CE certified

- After-sales service

- Professional R&D team

If you want to get more information about the ice cream production line, please feel free to consult us! WhatsApp/Phone: +86 13838385752.