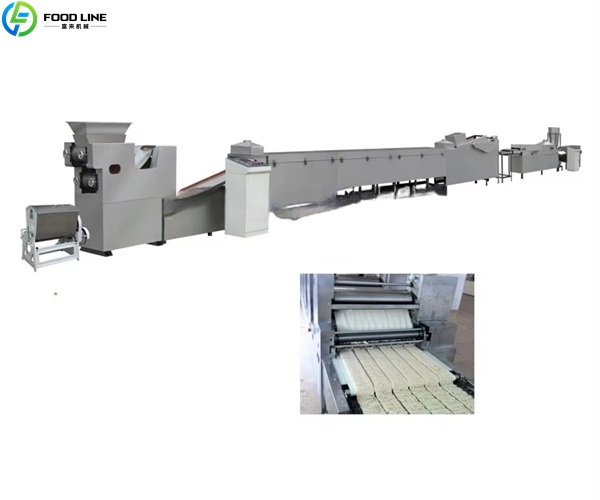

American Customers Purchase Instant Noodle Production Lines

A US instant noodle manufacturer specializes in producing high-quality instant noodles. Due to growing market demand, the company decided to expand its production capacity and install a new noodle production line. After extensive market research and comparisons, they chose our company as their partner and purchased our fried instant noodle production line.

Mr. John Carter commented, “Our company’s production needs are constantly expanding, and our traditional production line can no longer meet our production goals. After many communications and technical exchanges with your team, we decided to purchase this instant noodle production line. Since the equipment was put into operation, not only has production efficiency been greatly improved, but product quality has also been guaranteed, exceeding our expectations. In particular, it has helped us reduce operating costs in terms of energy consumption and production stability.”

Specifications of Noodle Production Line

| Equipment | Capacity / Volume | Power | Speed / Control | Material Specifications | Dimensions (L×W×H) | Weight | Other Features |

|---|---|---|---|---|---|---|---|

| Saline Mixing Tank | 1000 L | 1.5 kW | 280 rpm | Tank & Stirring Shaft: SUS304 Stainless Steel | 1000 × 1000 × 1000 mm | – | – |

| Double-Shaft Dough Mixer | 50 kg/batch | 5.5 kW | – | Food Contact Parts : SUS304 Stainless Steel | 1500 × 600 × 850 mm | ~250 kg | Discharge: Manual straight plate door Water Addition: Manual spray pipe |

| Dough Press Machine | – | 5.5 kW | Variable Frequency Speed Control | Press Rollers: Chilled Alloy Cast Steel Guard: Stainless Steel | 2800 × 600 × 1200 mm | – | Includes dough lapping device Roller Sizes: φ126×2, φ168×1, φ126×3 |

| Frying Machine | – | Main: 0.75 kW Oil Pump: 4 kW | Variable Frequency Speed Control | Pot: Carbon Steel Outer Guard: Stainless Steel | 8000 × 1300 × 1850 mm | ~4500 kg | Includes heating system, automatic temperature & oil level control |

| Air Cooler | – | 0.75 kW Fans: 0.37 kW x 5 | – | Conveyor Mesh, Support Rods: SUS304 Stainless Steel | 5000 × 800 × 1500 mm | ~1500 kg | – |

| Conveyor | – | 0.37 kW | – | Frame, Transmission, Feet: Carbon Steel Body: Stainless Steel | 2500 × 300 × 600 mm | ~80 kg | Includes frame, conveyor belt, transmission system |

Free Quote! WhatsApp/Tel: +86 13838385752.

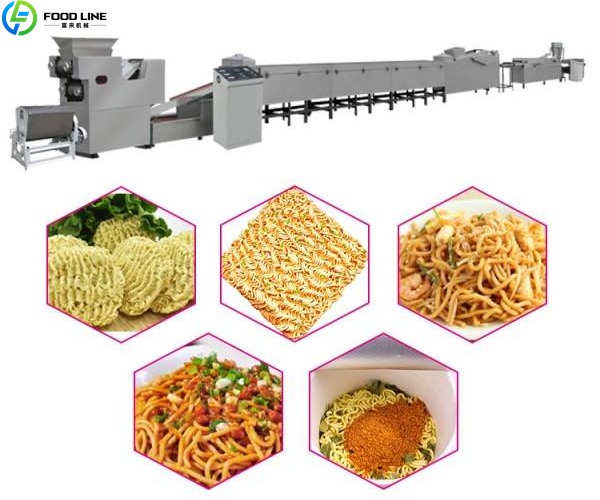

Features of Instant Noodle Production Line

Production

Fully automated operation ensures a more efficient and stable production process. Hourly output can reach 5,000 packs of instant noodles, meeting large-scale production needs.

Control

Advanced temperature control and recipe management ensure quality. Adjustments are made to the thickness of the noodles, frying time, and seasoning.

Energy Saving

Our production line minimizes energy waste while ensuring efficient production, effectively reducing production costs.

Finished Product

This line ensures crispy and high-quality instant noodles that meet international food standards.

Production Capacity

The line can flexibly adjust production speed and output to meet changing customer needs.

Design

The line’s modular design makes it easy to install and maintain. Users can add or remove production modules as needed, enhancing the line’s scalability.

Advantages of Instant Noodle Processing Line

Efficiency

Our Fried Instant Noodle Production Line utilizes an automated control system, reducing manual labor and ensuring uninterrupted production.

Quality

Throughout the production process, all noodles are guaranteed to meet customer requirements during frying, seasoning, and packaging. This ensures they meet customer expectations and enhances your brand image.

Cost Reduction

This line offers exceptional energy savings, reducing overall production costs.

Variety

Our line can adapt its production model to accommodate a variety of noodle varieties, meeting diverse consumer needs.

Why Choose Foodline Machinery

- CE certified

- After-sales service

- Professional R&D team

- Export experience

If you are also looking for reliable production line solutions, we will be your ideal partner. Welcome to contact us! WhatsApp/Phone: +86 13838385752.