Overview of Customers Purchasing Food UV Sterilization Machine

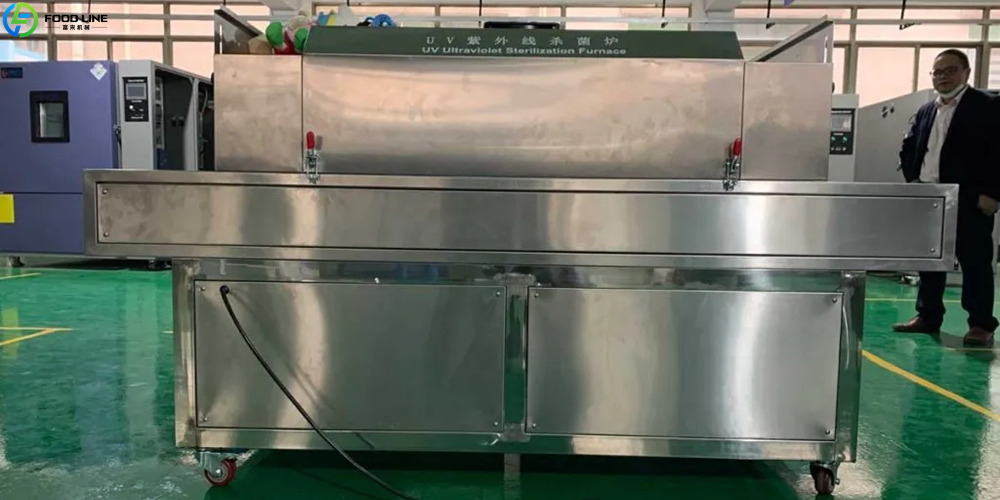

Our client is a US food processing company specializing in organic food and beverages, primarily targeting the health food market. Therefore, food safety and quality are top priorities. As their production scale expanded, they faced challenges in improving product hygiene and safety, reducing manual intervention, and increasing production efficiency. To meet these needs, they decided to invest in two advanced UV food sterilizers to ensure compliance with food safety standards.

During the purchase process, Purchasing Manager Emily Roberts stated, “When selecting a UV sterilizer, we prioritized efficiency and environmental friendliness. Our production process requires rapid, residue-free sterilization, and a UV food sterilizer meets these requirements.”

She added, “After comparing several companies, we chose Foodline’s UV food sterilizer. This equipment provides fast and effective sterilization, while also reducing the need for chemical disinfectants. Food safety has improved, and consumer feedback has been very positive.”

Overview of UV Food Sterilizer Machine

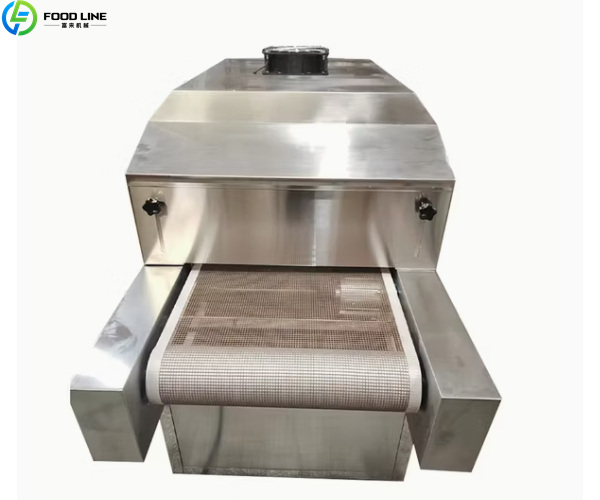

A UV food sterilization machine is a high-tech device that uses ultraviolet radiation to disinfect food. It is suitable for food processing, beverage production and packaging, pharmaceutical manufacturing, and other fields. It effectively removes microorganisms such as bacteria, viruses, and mold from food surfaces and packaging.

The machine uses ultraviolet light to illuminate the surface of food in a closed environment, achieving a contactless disinfection process. The high-intensity ultraviolet radiation can quickly penetrate the cell membranes of microorganisms and destroy their DNA or RNA structures, ultimately achieving the purpose of sterilization.

Free Quote! WhatsApp/Tel: +86 13838385752.

Specifications of UV Food Sterilizer Machine

| Parameter | Specification |

|---|---|

| Total Equipment Length | 2000 mm |

| Working Zone Length | 1000 mm |

| Feeding Zone Length | 500 mm |

| Discharging Zone Length | 500 mm |

| Entrance / Exit Height | 200 mm |

| Conveyor Belt Width | 500 mm |

| Conveyor Belt Height (from floor) | 750 ±20 mm |

| Number of UV Lamps | 16 |

| Power per UV Lamp | 20 W |

Characteristics of UV Sterilization Machine

- Sterilization: Ultraviolet radiation kills most bacteria, viruses, and mold in a short period of time, ensuring food hygiene and safety.

- No Chemical Residue: Compared to traditional chemical sterilization methods, UV sterilization produces no chemical residue, meeting food safety requirements.

- Environmentally Friendly: The equipment consumes only electricity during operation and does not require chemicals, reducing environmental pollution. UV sterilization is highly efficient and saves energy.

- Applicability: This UV food sterilizer is suitable for sterilizing a variety of foods, including fruits and vegetables, prepared foods, beverages, and dairy products.

- Control System: Equipped with a digital control system, it adjusts the UV lamp intensity and exposure time to ensure effective disinfection.

Advantages of UV Sterilization

- Efficiency: UV sterilization is rapid, completing sterilization within seconds to minutes.

- Safety: UV sterilization does not adversely affect food, nor does it alter its nutritional content or flavor.

- Cost Reduction: UV sterilization eliminates the need for chemical disinfectants, reducing the cost of purchasing and using chemicals.

- Reliability: Our UV food sterilizers are constructed from high-quality materials, ensuring stability and durability.

Working Principle of Food Ultraviolet Sterilization Machine

UV food sterilization machines utilize ultraviolet radiation (specifically at a wavelength of 253.7 nm) to sterilize food. When bacteria, viruses, or other microorganisms are exposed to UV radiation, it penetrates their cell membranes and nucleic acids, disrupting the molecular structure of their DNA or RNA, rendering them incapable of reproduction or even killing them.

The machine’s internal configuration includes multiple UV lamps (16 x 20W) evenly distributed within the work area, ensuring that every surface of the food is irradiated. The UV lamps emit light with an intensity of 160 microwatts per square centimeter, effectively killing a wide range of bacteria, viruses, and mold. The UV radiation not only directly affects the food surface but also treats microorganisms on the surface of food packaging, providing comprehensive product safety.

Why Choose Foodline Equipment

- Quality Assurance

- Technology

- Customization Services

- After-Sales Service

If your company is also looking for efficient and safe food disinfection solutions, we will provide you with the most suitable UV sterilization machine to help you improve food safety and production efficiency. Welcome to consult! WhatsApp/Phone: +86 13838385752.