Michael Anderson, a bakery owner from the United States, runs a chain of bagel and other baked goods shops. His shop is incredibly popular, with a growing number of customers each day. As demand grew, manual production methods were no longer able to meet the volume of orders. They also suffered from low efficiency and inconsistent bagel sizes. To improve production efficiency and ensure the quality of his bagels, Michael compared various options and ultimately chose our bagel maker. After using the machine, he commented:

“This bagel making machine has exceeded my expectations. It can produce 2,000 bagels per hour, saving a lot of manpower. The finished products are uniform in size and have a smooth surface. Customer feedback has been very positive. This machine has helped us overcome production bottlenecks.”

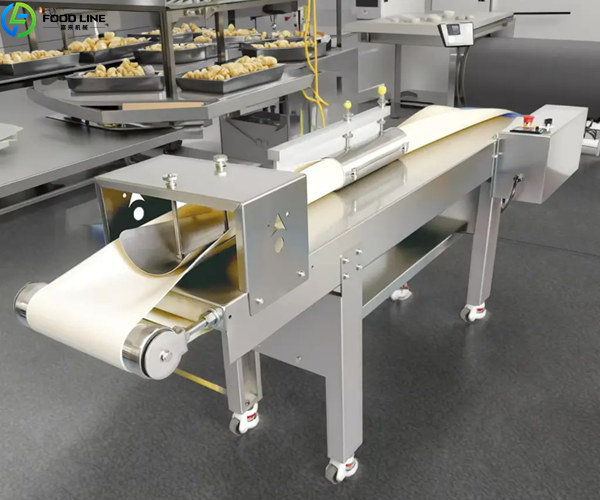

Bagel Forming Machine Overview

This bagel maker machine is designed for high-volume production. It consists of an inlet, conveyor belt, control panel, conveyor belt switch, discharge port, and universal wheels. The operator simply places dough into the inlet, and the machine automatically forms the dough, discharging uniformly sized bagels from the discharge port.

The machine can produce up to 2,000 bags per hour, and its molds are customizable and adjustable to meet diverse business needs.

Specifications of Bagel Maker Machine

| Specification | Value |

|---|---|

| Product Name | Bagel Forming Machine |

| Model | FL-BG350 |

| Voltage | 220V / 380V |

| Power | 0.55 KW |

| Forming Weight Range | 30-150 g/pc |

| Output Capacity | 2000 pcs/hour |

| Overall Dimensions | 21506001150 mm |

| Packaging Dimensions | 2180630600 mm |

| Net Weight / Gross Weight | 125 kg / 150 kg |

| Remarks | One mold included as standard |

Overview of the Bagel Machine Market in the United States

The United States is one of the leading consumer countries for bagels. Bagels have become a staple of breakfast and fast food. The US baking market continues to grow, with bagel demand remaining stable year after year. Consumers are not only seeking taste and nutrition, but also increasingly focusing on product appearance. Against this backdrop, the demand for automated bagel making machines has risen rapidly.

Features of Bagel Making Machine

- Customizable Molds: Different sizes can be customized according to customer needs. And mold dimensions are adjustable.

- Excellent Molding Results: Bagels are uniform in size, shape, and surface.

- High Efficiency: 2,000 pieces per hour can be produced, increasing production capacity.

- Speed: Equipped with a belt speed controller. The molding speed can be adjusted according to process requirements.

- Operational Design: Intuitive control panel (including conveyor switch). Even novice operators can quickly learn how to use the machine.

- Stable Weight: The dough weight corresponding to the mold fluctuates by only ±10g, ensuring product quality.

- Integration into a Production Line: The machine can be operated as a stand-alone unit or integrated with a block divider and other equipment.

Advantages of Bagel Forming Equipment

- Production Efficiency: Compared to manual operation, bagel maker machines offer higher production efficiency.

- Reduced Labor Costs: Automation reduces reliance on workers, saving labor costs.

- Ensuring Product Quality: Standardized production ensures consistent bagel sizes, helping to build brand image.

- Diversified Needs: Customizable molds support the production of various product sizes.

- Easy to Move and Clean: The machine is equipped with universal wheels for easy mobility. The conveyor belt is designed for easy cleaning.

About Foodline Equipment

- R&D Capabilities: We have our own R&D team, continuously optimizing our design and production processes.

- Quality Control: All equipment is CE-certified.

- Customization: We can customize mold dimensions to meet your production needs.

- Service: We provide installation guidance, operator training, and long-term maintenance support.

- Export Experience: Our products have been exported to numerous countries and regions.

If you also want to buy a bagel machine, welcome to consult and get a quote! WhatsApp/Phone: +86 13838385752.