A liquid filling and sealing machine is an automated device designed to streamline the packaging process for liquid products through precise filling and sealing capabilities. It is specifically designed to handle specific liquid types, particularly low-viscosity, highly fluid, and particle-free water-based or oil-based liquids. This targeted design ensures optimal performance, as the machine’s internal structure is customized to avoid clogging and inefficiencies that can occur when handling thicker or particulate-containing liquids.

Whether you’re working in a large factory or a medium-sized production facility, this liquid filling and sealing machine reduces manual intervention and minimizes errors. Contact us for more information! WhatsApp/Phone: +86 13838385752.

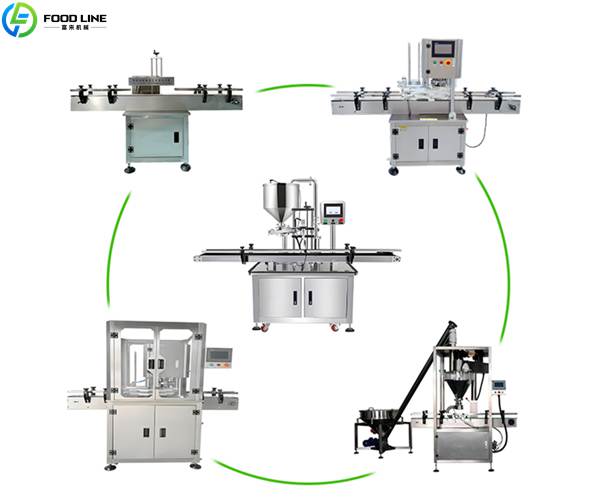

Filling Machine Equipment

| Parameter | Specification |

|---|---|

| Filling Range | 100–10000ML (customized according to customer requirements) |

| Filling Speed | 1–50 Bottles/min (Take 6 heads of 500ml as an example) |

| Working Pressure | 0.6–0.8MPA |

| Bin Volume | About 140L |

| Machine Size | About 330011602040 mm (length * width * height) |

| Machine Weight | About 450KG |

| Measurement Accuracy | 0.3% – 1% (Depending on the specific material) |

| Power/Voltage | 1–8KW, 220V/380V |

Liquid Filling and Sealing Machine Applicable Products

This filling and sealing machine is optimized for water-based or oil-based, low-viscosity, particle-free liquids and is suitable for the following three product categories:

- Daily necessities: Laundry detergent, shampoo, shower gel, hand soap, and liquid soap. These products require stable filling and a secure seal to prevent leakage during transportation.

- Food: Cooking oil, soy sauce, vinegar, juice, carbonated beverages, and liquid condiments. Hygiene and precision are crucial to ensure product safety and compliance.

- Industrial products: Lubricants, paint thinners, water-based coatings, and industrial cleaning fluids. The machine’s robust design can handle the chemical characteristics of these liquids, ensuring safe and efficient packaging.

Features of Filling and Sealing Machine

Precision Filling Control

This liquid filling and sealing machine is equipped with an advanced flow meter and servo motor to ensure precise filling with minimal tolerance. Precision is crucial for low-viscosity liquids, as they can easily splash or distribute unevenly if not strictly controlled. The nozzle features a drip-proof design to prevent residual liquid from affecting packaging cleanliness.

Multiple Sealing Modes

This machine supports a variety of sealing methods, depending on the packaging type (bottle, bag, or can). For example, in daily chemical production, it can efficiently seal plastic bottles of shampoo with screw caps.

Intelligent Operating System

The machine features a user-friendly touchscreen interface, allowing operators to easily set parameters such as fill volume, sealing temperature, and production speed. The system also features a self-diagnostic function that alerts users to issues such as nozzle clogs or insufficient liquid supply, reducing downtime.

Adjustable Capacity

The machine’s output can be adjusted to meet production needs, ranging from 100 to 10,000 ml per hour. This flexibility makes it suitable for both small-batch trial production and large-scale mass production, and can adapt to the dynamic needs of different industries.

Advantages of Filling Machine

Improved Production Efficiency

The liquid filling and sealing machine integrates filling and sealing into a continuous process, eliminating the need for manual transfer between different workstations. This significantly reduces production time compared to traditional stand-alone equipment.

Reduced Costs

Automation reduces labor costs, while precise filling minimizes material waste, which is particularly important for high-cost liquids such as edible oils and industrial lubricants. The machine’s durable components also reduce maintenance frequency and long-term operating costs.

Compliance with Hygienic Standards

The machine’s contact areas are constructed of food-grade stainless steel, meeting the stringent hygiene requirements of the food and daily chemical industries. Easy disassembly and cleaning prevent cross-contamination between different liquid products.

Stable Sealing Performance

An airtight seal prevents leakage and oxidation, extending the shelf life of products. For example, in the industrial sector, well-sealed lubricant bottles prevent moisture intrusion, ensuring product stability during storage and transportation.

FAQ

No, this machine is not designed for liquids containing particles. Particles can clog the nozzle, damage internal components, and affect filling accuracy. It is suitable only for low-viscosity liquids that do not contain particles.

Yes, it supports containers of varying shapes and sizes (100 ml to 10,000 ml bottles). Operators can adjust the nozzle height and sealing mechanism to match specific container sizes.

No, a detailed maintenance manual is provided to guide operators.

Why Choose Foodline Machinery?

When choosing a liquid filling and sealing machine, partnering with a reliable manufacturer is key to ensuring long-term performance. Our company stands out thanks to three core strengths:

- Customization Expertise: Whether you need a compact machine for small-batch juice production or a high-speed production line for industrial lubricants, we can select a machine tailored to your specific needs. Our team helps customers select a model based on their specific requirements.

- Reliable Quality: All of our liquid filling and sealing machines undergo rigorous testing to ensure durability and stability.

- Comprehensive Support: We offer 24/7 technical support, remote installation guidance, and operator training. We provide one-stop service from production to after-sales service, ensuring your production line runs smoothly.

By choosing the right equipment and partners, companies can improve productivity, reduce costs, and ensure product quality. Contact us for a quote and personalized solutions! WhatsApp/Phone: +86 13838385752.