Spanish Beverage Company Purchases Filling Capping Machine

A Spanish company specializes in producing natural, additive-free, cold-pressed juices and smoothies. As market demand for its products increased, its existing semi-automated filling equipment became a major bottleneck. The equipment’s slow speed and poor accuracy resulted in inconsistent bottle filling levels and occasional leaks, which not only wasted raw materials but also damaged the company’s brand image.

After research, Purchasing Director Carlos Rodríguez ultimately chose to partner with us, installing two fully automated rotary bottle filling and capping machines. After using the machine, he commented, “We researched several manufacturers before deciding to purchase. We ultimately chose Foodline Machinery not only for their price, but also for their professional equipment. Our product contains fruit pulp fibers, which places high demands on the filler’s anti-clogging design and valve nozzle precision. Their technical team provided us with a detailed test report and customized solution, which allayed our concerns. This filling and capping machine operates very stably, with filling levels accurate to the millimeter, ensuring product quality. More importantly, the screw cap seal meets standards, reliably guaranteeing the product’s shelf life. This equipment is more than just a machine; it’s a strategic partner in achieving our annual sales growth goals.”

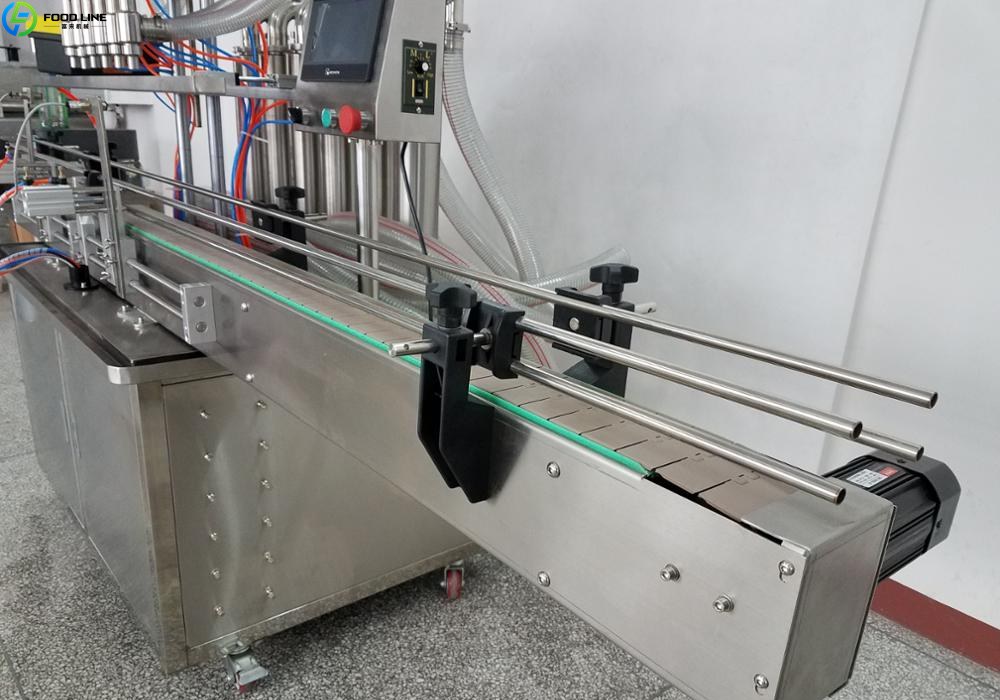

Filling and Capping Machine Overview

The bottle filling and capping machine is a fully automatic system that integrates filling, capping, and capping. Made of high-quality materials, it meets food industry hygiene and safety standards. Its core design concept is to achieve both high speed and high precision. It can be integrated into existing production lines and is suitable for products in sizes ranging from 100ml to 10,000ml.

Bottle Filling and Capping Machine Overview

| Specification | Details |

|---|---|

| Filling range | 100–10000ML (customized according to customer requirements) |

| Filling speed | About 1–50 (Bottle/min) |

| Working pressure | 0.6–0.8MPA |

| Bin volume | About 65L |

| Machine size | About 180*810*1530mm |

| Machine weight | About 200KG |

| Measurement accuracy | ≤5g (Take 20 pumps as an example) |

| Power/voltage | 2.5KW/220V |

Features of Commercial Filling Machines

Fully automated

The entire process, from empty bottle delivery to filling, capping, and finished product delivery, is fully automated. This reduces manual intervention, labor costs, and contamination risks.

Filling System

Utilizing advanced servo control system technology, it ensures that liquids of varying viscosities are filled with a precision tolerance of less than 5g.

Capping Head

Equipped with a magnetic torque capping head, it smoothly handles caps of varying materials and specifications, ensuring a tight seal.

PLC Control

Combined with a touchscreen human-machine interface, parameter setting, production data monitoring, and fault diagnosis are clear and easy to operate.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Automatic Bottle Filling and Capping Machine

Production Efficiency

High-speed filling and capping capabilities increase overall production line output, helping companies meet market demand.

Reduced Waste

High-precision filling eliminates costly losses and significantly reduces raw material costs.

Quality

Stable performance and precise control ensure consistent fill volumes and tight seals.

Stability

The robust mechanical structure and carefully selected materials for core components ensure the equipment is capable of high-intensity, continuous production with minimal failure rates.

Liquid Filling and Capping Machine Application Industry

- Food Industry: Various juices, beverages, etc.

- Daily Necessities Industry: Can be used in shampoo, shower gel, hand soap, etc.

- Industrial Industry: Suitable for automotive fluids, lubricants, chemical reagents, etc.

Why Choose Foodline Machinery

- CE certification

- After-sales service

- Export experience

If you are also looking for equipment to improve your packaging production capabilities, please contact us. WhatsApp/Phone: +86 13838385752.