Customer Overview and Purchase Background

Michael Anderson, owner of a mid-sized meat processing company in the United States, was looking for advanced equipment to improve production efficiency. His company specializes in smoked ham, cured chicken breast, and ready-to-eat seafood products, all of which are increasingly popular with American consumers seeking convenient and delicious meals.

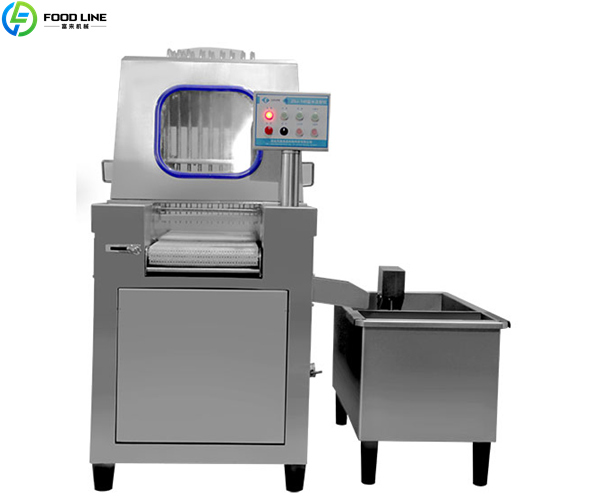

After researching several international suppliers, Michael contacted our company. He explained that his production line was facing numerous challenges: uneven brine distribution in large cuts of meat, time-consuming manual brine application, and significant yield losses. After discussions and a video demonstration, he decided to purchase our meat brine injector.

Michael commented after the installation: “This machine has exceeded my expectations. The brine injection is even, the meat quality is improved, and the product yield has increased significantly. It has significantly increased my profits.”

Parameters of Meat Brine Injector Machine

| Parameter | Specification |

|---|---|

| Model | FL-120 |

| Injection Needles | 120 pcs |

| Production Capacity | 500-1500 kg/h |

| Motor Power | 1.5 kW (Variable Frequency) |

| Water Pump Power | 3 kW |

| Water Pump Pressure | 2 — 6.3 kg (adjustable) |

| Tank Width | 420 mm |

| Needle Vertical Stroke | 170 mm |

| Injection Speed | Variable Frequency Control |

| Chain Step Distance | 120 mm |

| Optional Needle Spec. | Ø304 mm |

| Host Machine Dimensions | 1350*1250*1720 mm |

| Feeder Cart Dimensions | 860*460*650 mm |

| Weight | 550kg |

Market Situation of Meat Brine Injector in the United States

The US meat processing industry is one of the most advanced in the world, with consumers demanding high-quality, tender, and flavorful products. The market for cured and ready-to-eat meats has grown steadily in recent years, particularly in supermarkets, convenience stores, and online food delivery platforms.

To meet these demands, US processors are increasingly turning to automated solutions, such as meat brine injection machines. These machines help companies improve quality and reduce labor costs. With the rise of barbecue culture and processed meats like bacon, deli meats, and smoked poultry, the demand for reliable meat brine injection equipment is only expected to increase.

Free Quote! WhatsApp/Tel: +86 13838385752.

Key Features of the Brine Injector Machine

Our equipment is designed for practicality and efficiency. Its outstanding features include:

Durable Stainless Steel Construction

The entire machine is constructed of food-grade SUS304 stainless steel, meeting US food hygiene standards and ensuring long-term durability.

Intelligent Needle Protection System

The injection needle is equipped with an automatic lifting mechanism to prevent breakage or damage upon contact with bone, ensuring safe processing of bone-in meat.

Advanced Filtration and Circulation System

The built-in filtration system removes fine meat particles from the brine, preventing clogging of the pump and needle, while the circulation mechanism maintains constant injection pressure.

Easy Maintenance and Cleaning

The removable chain plate and modular design allow for quick cleaning, saving time and ensuring hygienic production.

Advantages of Using a Meat Injector Machine

Compared to traditional manual marinating, meat injection machines offer multiple advantages to meat processors:

Reduced Processing Time

Brine can be evenly injected into the meat in a short time, significantly reducing marinating time.

Increased Yield

Optimized brine absorption ensures higher product yields and reduces raw material waste.

Enhanced Flavor and Taste

The machine ensures even brine distribution, improving taste.

Improved Labor Efficiency

Automation reduces the need for manual labor, helping companies reduce costs and address labor shortages.

High Quality and Food Safety

Each batch maintains the same high quality and meets strict U.S. food safety regulations.

Applicable Products

This meat brine injector is highly versatile and can be used extensively in the US meat processing industry. Typical applications include:

- Pork

- Beef

- Poultry

- Seafood

- Processed foods

Why Michael Chose Foodline Machinery

Here’s what Michael Anderson chose our company for:

- Proven Expertise: We have many years of experience supplying machining equipment worldwide, and our reliability is evident in case studies and customer feedback.

- Tailored Solutions: Our team provided personalized consultation to ensure the equipment met his production line requirements.

- After-Sales Support: We offer a full range of services, from installation guidance to training and ongoing technical support.

Michael Anderson‘s case study highlights how adopting a meat brine injection machine can help meat processors stay competitive in a rapidly evolving market. Our meat brine injection machines are the perfect choice for businesses looking to improve the yield and quality of their meat products. Contact us today to learn how we can help you achieve your production goals. WhatsApp/Phone: +86 13838385752.