Overview of Italian Customers Purchasing Powder Filling Machines

An Italian manufacturer primarily produces Italian coffee powder, cocoa powder, and roasting ingredient powders. With business expansion, their existing semi-automatic filling line encountered problems: capacity bottlenecks, fluctuations in weight accuracy, and dust pollution.

To solve these issues, Luca‘s team compared and evaluated three local and international suppliers. They ultimately chose our powder filling machine. They were very satisfied with the equipment’s automation integration capabilities, food-grade material compliance, and energy efficiency.

Luca Martini commented after using the equipment: “After using it, the filling accuracy has been significantly improved. The reduced error has allowed us to lower material costs and strictly adhere to legal standards for net content. Automation reduces the need for professional personnel and saves time during peak hours. In addition, the vacuum feeding and anti-static shielding design improve the working environment and safety. The after-sales service is also very professional. Technical issues are responded to within 24 hours, and calibration problems are resolved within minutes.”

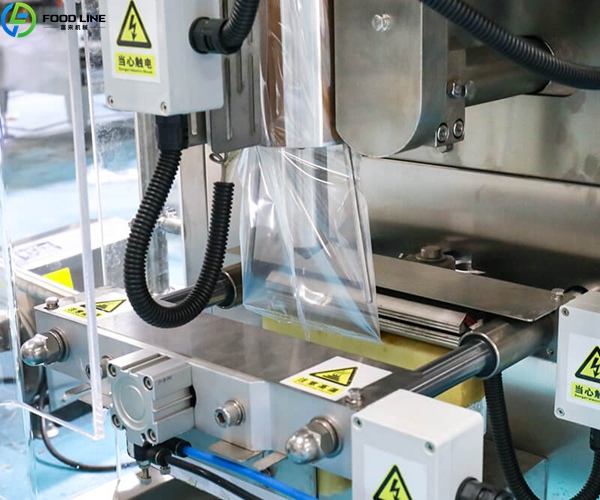

Powder Filling and Sealing Machine Overview

The powder packaging machine is a filling solution designed for medium- to high-speed production. It is suitable for powders and fine granular materials, enabling continuous operation from raw material conveying, metering and filling, online detection, to discharge. The core components include a vacuum feeding system, a vibrating screen and material level control, a high-precision weighing and filling head, and a human-machine interface.

Specifications of Packaging Machine

| Model | FL – 300 | FL – 600 | FL – 900 |

|---|---|---|---|

| Lanes | 2-4 Lanes | 3-10 Lanes | 4-16 Lanes |

| Bag Width | 20-70mm | 20-95mm | 20-105mm |

| Film Width | Max: 300mm | Max: 600mm | Max: 900mm |

| Sealing Type | Back Seal | Back Seal | Back Seal |

| Packing Speed | 20-40 bags/lane/min | 20-40 bags/lane/min | 20-40 bags/lane/min |

| Measuring Method | Long screw / Short screw / Short screw with cup | Long screw / Short screw / Short screw with cup | Long screw / Short screw / Short screw with cup |

| Cutting Type | Straight / Zig-zag / Round / Die-cut | Straight / Zig-zag / Round / Die-cut | Straight / Zig-zag / Round / Die-cut |

| Bag Length | 50mm ~ 180mm | 50mm ~ 180mm | 50mm ~ 180mm |

| Power Supply | 50Hz / 220V / 3.5kW | 50Hz / 220V / 5.5kW | 50Hz / 220V / 7.5kW |

| Dimension (mm) | 1900*1440*3130 | 1860*1750*3200 | 1860*2050*3300 |

| Weight | approx. 900 kg | approx. 1200 kg | approx. 1500 kg |

Contact Us! WhatsApp/Phone: +86 13838385752.

Powder Filling Machine Applicable Products

- Food powders: coffee powder, cocoa powder, milk powder, flour, etc.

- Nutritional and health products: protein powder, meal replacement powder, vitamin powder, etc.

- Industrial and daily chemical products: detergent powder, paint powder, ceramic powder, etc.

Features of Powder Filling Equipment

- Automation: Automated operation from raw materials to finished product, reducing manual intervention and secondary contamination.

- Metering: Electromagnetic vibrating filling head, dynamic weighing and automatic replenishment, minimizing error.

- Hygiene: Food-grade materials, quick-cleaning design, compliant with EU food contact regulations.

- Modular: Supports multiple packaging and specification switching, with the ability to add labels and seal cans.

- Data Management: Real-time monitoring of output, pass rate, and raw material consumption, with support for data export.

Advantages of Powder Bag Filling Machine

- Capacity: Continuous operation design, single-line filling speed can reach 20-40 packs/minute.

- Cost: Improved weight accuracy reduces material loss, and optimized energy consumption lowers operating costs.

- Quality: Avoids net content fluctuations and contamination risks caused by manual operation.

- Maintenance: Modular structure facilitates inspection and cleaning, supporting rapid changeover between multiple product lines.

Why Choose Foodline Equipment

- CE Certification

- After-sales Service

- Professional R&D Team

If you are interested in this powder filling machine, please feel free to contact us for a quote and information! WhatsApp/Phone: +86 13838385752.