Customer Purchase Overview

Michael Anderson, owner of a medium-sized meat processing plant in the United States, began searching for advanced equipment to improve the efficiency of his production line. His company specializes in producing a variety of sausages, including fresh pork, chicken, and smoked sausages, for supermarkets, restaurants, and local chain stores.

Michael shared his experience: “Our workers often spent a lot of time manually tying sausages, which was not only labor-intensive but also resulted in inconsistent product appearance. After researching various suppliers, I stumbled upon Foodline Machinery’s sausage knotting machine. From the first demonstration, I knew this machine would help us take efficiency and quality to the next level.”

After a smooth purchasing process, Michael‘s factory successfully integrated the sausage knotting machine into the production line, and it quickly became one of the most reliable equipment in the factory.

Specifications of Automatic Sausage Tying Machine

| Model | FL-I | FL-II |

|---|---|---|

| Power (kW) | 1.5 | 3 |

| Voltage (V) | 220 | 220 |

| Suitable Object Diameter (mm) | φ9~28 | φ9~28 |

| Single Crystal Length (mm) | 10~300 | 10~300 |

| Production Capacity (L/min) | 10~200 | 100~600 |

| Dimensions (mm) | 1100×550×1200 | 1100×850×1250 |

Market Situation of Sausage Knotting Machine in the U.S.

The United States is one of the world’s largest consumers of processed meat. Demand for sausage continues to grow, driven by its popularity in both retail and foodservice settings. With the rise of ready-to-eat meals, supermarkets and restaurants are seeking suppliers who can deliver high-quality, high-volume sausage production.

At the same time, high labor costs and increasingly stringent food safety regulations in the United States have prompted many meat processing companies to invest in automation. In this environment, automatic sausage knotting machines have become a vital option for companies seeking to strike a balance between cost control and product quality. Medium- and large-scale sausage manufacturers, in particular, are increasingly adopting sausage knotting machines to streamline their operations. This shift reflects a broader trend in the U.S. food processing industry: automation is becoming a necessity to stay competitive.

Sausage Tying Machine Features

Our automatic sausage knotting machine is designed with practicality, durability, and efficiency in mind. Key features include:

Stainless Steel Construction

This machine is constructed of high-quality stainless steel, making it corrosion-resistant, easy to clean, and fully compliant with food safety standards.

Compact Design

Although it has powerful features, the machine is compact. Therefore, it integrates seamlessly into existing production lines, and it does not require major equipment modifications.

Adjustable Sausage Length

Operators can easily set different sausage lengths based on sausage size and casing type, ensuring production flexibility.

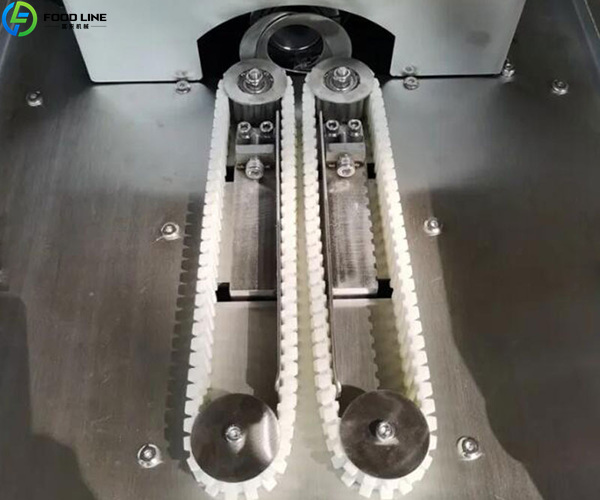

Consistent Knot Strength

The machine ensures uniform knots, giving sausages a professional appearance and a stable structure.

User-friendly Control System

The simple interface makes the device easy to operate, requiring minimal training for staff.

Advantages of Automatic Sausage Tying Machine

Our automatic sausage knotter offers significant advantages over manual knotting and other traditional equipment:

Improved Efficiency

The machine can knot hundreds of sausages per minute, significantly reducing manual labor and increasing daily production.

Guaranteed Product Quality

Uniform knots enhance the overall appearance of sausages, satisfying the demands of supermarkets and high-end retailers.

Labor Cost Savings

By reducing reliance on manual labor, businesses can significantly reduce operating costs and reallocate workers to other value-added tasks.

Durability and Reliability

The sausage knotter is designed for long-term operation, maintaining high performance and minimizing downtime.

Why Choose Foodline Machinery

There are numerous equipment suppliers in the global market, but Michael and many other US customers chose us for the following reasons:

- Industry Expertise: With years of experience designing food processing machinery, we understand the demands of meat equipment.

- Customized Solutions: We offer customization options to ensure our equipment perfectly matches your production line.

- Reliable After-Sales Support: We provide installation guidance, operator training, and remote technical support to ensure customers can use their equipment normally.

This case study highlights how our sausage knotting machine helped a US meat processing company increase productivity, reduce costs, and improve product quality. As demand for automation grows in the US food industry, companies that invest in equipment like automatic sausage knotting machines will be better positioned to meet market demands and remain competitive. For meat processing companies, our machines represent more than just an equipment upgrade. They represent a strategic investment. Welcome to consult and get a quote! WhatsApp/Phone: +86 13838385752.