In the pastry industry, consumer demands for taste, appearance, and innovation continue to rise. The automatic encrusting machine is a highly efficient and intelligent device. Small pastry encrusting machines are a powerful tool for manufacturers to improve production efficiency, reduce costs, and enhance product quality. Welcome to consult and get a quote! WhatsApp/Phone: +86 13838385752.

Encrusting Machine Overview

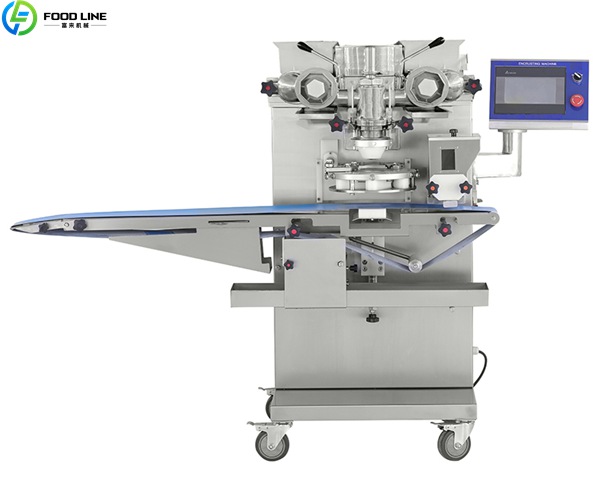

The automatic encrusting machine is a specialized production machine designed for making a variety of stuffed pastries. It utilizes automated technology to efficiently and stably encrust fillings and form the crust. Whether it’s mochi, mooncakes, cookies, or more innovative stuffed foods, this machine precisely controls the crust-to-filling ratio to ensure the product’s appearance and taste.

Through intelligent operation via a PLC control panel, the small pastry encrusting machine can adjust product size, crust-to-filling ratio, and product length. Furthermore, the use of high-quality imported components ensures stable operation and a longer lifespan.

Parameters of Automatic Encrusting Machine

| Model | FL – AE01 |

|---|---|

| Production Output | 5-50 pcs/minute |

| Product Weight | 1-50 g/pc |

| Skin to Filling Ratio | 1:9 – 9:1 |

| Voltage | 220V |

| Power | 1.3 kW |

| Net Weight | Approx. 100 kg |

| Machine Dimensions | 1.2×0.8×1.0 (m) (L×W×H) |

| Packing Volume | 1.0×1.5×1.4 = 2.3 m³ |

Free Quote! WhatsApp/Tel: +86 13838385752.

Applicable Products of Small Pastry Encrusting Machine

- Mooncakes: Includes traditional flavors as well as newer offerings like fruit mooncakes and ice cream mooncakes.

- Mochi: Mochi in various flavors.

- Biscuits: Biscuits such as two-flavored and two-color biscuits.

- Glutinous Rice Balls: Dry glutinous rice balls and qingtuan (green rice balls).

- Specialty Snacks: Crystal fruit cakes, pumpkin cakes, taro dumplings, and Sichuan sesame cakes.

- Pet Food and Snacks: Sesame balls, meat pies, and finger biscuits.

Working Principle of Encrusting Equipment

Raw Material Feeding

The machine automatically feeds the dough and filling into the dough and filling hoppers, respectively, through thickened stainless steel hoppers. Each hopper holds 3 kg of raw material.

Dough-to-Filling Ratio Control

A PLC intelligent control system allows the operator to adjust the dough-to-filling ratio according to needs.

Automatic Encrusting and Forming

The machine system ensures that the filling is perfectly enclosed, the outer layer is smooth, and the filling is evenly distributed.

Cutting Output

Imported wear-resistant arc-shaped cutters ensure consistent product size.

Features of Automatic Encrusting Equipment

Configuration

Utilizes Taiwan Delta inverters and Taiwan Sehye and Taiwan Liming brand motors for stable performance, ensuring long-term equipment operation and avoiding breakdowns and downtime.

Intelligent Control

The PLC intelligent touch screen system allows for easy adjustment of machine parameters based on production needs. Operation is simple and convenient, making it suitable for production of all sizes.

Wear-Resistant and Durable

The Teflon-coated stainless steel hopper is non-stick and wear-resistant, making it easy to clean and extending its service life.

Adaptability

The machine can produce everything from traditional pastries to innovative stuffed foods. Available discharge molds in large, medium, and small sizes meet the production needs of diverse foods.

Space Cost

The machine occupies a small footprint and features a high degree of automation, significantly reducing labor costs and improving production efficiency.

Advantages of Pastry Encrusting Machine

Production Efficiency

Fully automated operation achieves a production speed of 5-50 pieces per minute, shortening production cycle times.

Quality

Precise control of the dough-filling ratio ensures product quality and taste, reducing errors associated with manual operation.

Cost Savings

Automated processes reduce reliance on manual labor, minimize raw material waste, and lower production costs.

Diversity

Capable of producing a wide variety of stuffed foods in various sizes, meeting market demand for personalized and customized products.

Maintenance

High-end equipment minimizes malfunctions, and durable materials simplify maintenance and cleaning.

FAQ

This machine supports wrapping a variety of fillings and crusts, including traditional pastries. It can also handle modern and innovative products such as ice cream mooncakes, mochi ice cream, and even pet food.

The machine has a production capacity of 5-50 products per minute, depending on the size and complexity of the product. The weight of each product can be adjusted between 1-50 grams to meet the production needs of different specifications.

The PLC control panel allows you to adjust the dough-to-filling ratio, product size, and length. This allows you to adjust the dough-to-filling ratio to your needs, controlling product weight and shape to ensure consistent food production.

About Foodline Machinery

- CE certified

- After-sales service

- Professional R&D team

Choosing us, you will not only get an efficient machine, but also a reliable partner. In addition, we also have bagel-forming machines. Contact us! WhatsApp/Phone: +86 13838385752.