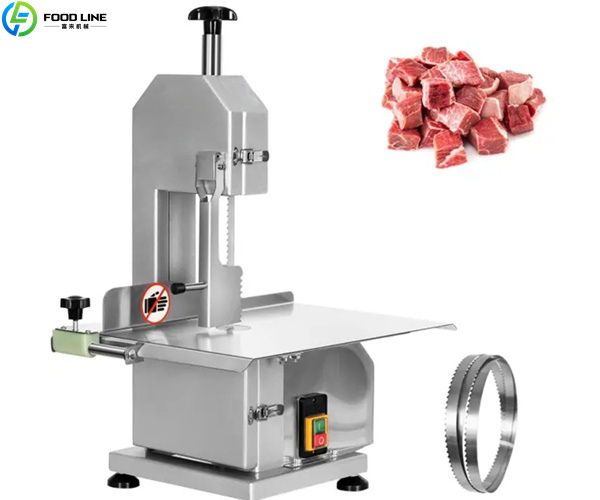

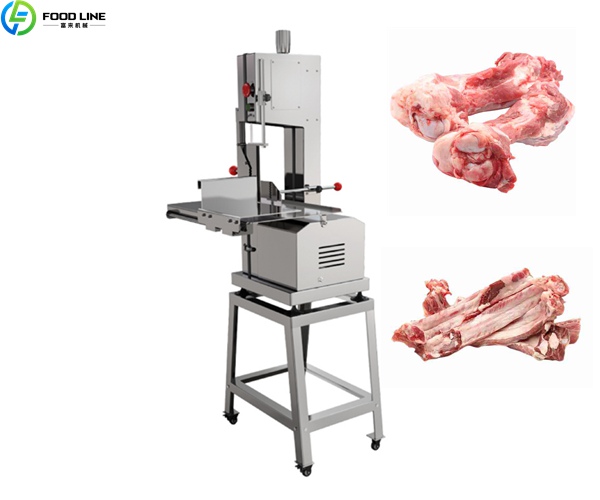

In the food production industry, choosing an efficient, safe, and durable commercial bone saw machine not only improves cutting efficiency but also ensures neat cuts. This 330 commercial bone saw machine, designed in stainless steel, offers sharp cutting performance and a safe operating structure, making it ideal for all meat processing applications. Whether it’s fresh meat, frozen meat, or large, tough bones, it can easily cut through them, helping businesses improve production efficiency. Contact us for a quote! WhatsApp/Phone: +86 13838385752.

Parameters of the Bone Sawing Machine

| Model | FL-B330 |

|---|---|

| Blade Length | 2070 mm |

| Blade Speed | 15 m/s |

| Voltage | 220V |

| Power | 1100W |

| Max Cutting Height | 0–330 mm |

| Max Cutting Thickness | 5–190 mm |

| Worktable Size | 610 × 430 mm |

| Overall Dimensions | 630 × 560 × 1070 mm |

| Net Weight | 60 kg |

Features of Commercial Bone Saw Machine

Stainless Steel Construction

The machine body, worktable, and protective components are all made of food-grade stainless steel. They are corrosion-resistant and rust-resistant, ensuring long-term stable performance in humid and high-intensity working environments. They are also easy to clean and meet international hygiene standards for food processing.

Cutting System

Utilizing a 2070 mm high-strength blade belt and a stable operating speed of 15 m/s, it delivers precise and consistent cutting results. This reduces food waste and ensures a smooth, even surface finish.

Safety Design

The bone sawing machine features a safety pressure plate, blade guard, and emergency stop switch. These features effectively reduce operational risks and protect workers, even during high-frequency cutting operations.

Power

The 1100W high-power motor provides ample torque. It easily handles challenging cutting tasks, such as thick bones and large pieces of frozen meat, and maintains stable output even during extended operation.

Cutting Size

The cutting height can be adjusted up to 330 mm, and the thickness range is 5–190 mm. This allows for flexible adaptation to different ingredients and processing requirements, enhancing the machine’s versatility.

Tabletop Design

A small footprint (630 × 560 mm) allows for easy placement in small kitchens or processing rooms, without compromising operating space for other equipment.

Interface

The control panel features a well-organized layout, responsive buttons, and simple, intuitive operation. This allows employees to quickly master the system without extensive training, improving work efficiency.

Advantages of Bone Sawing Machines

Productivity

Compared to traditional manual bone saws, this meat and bone saw machine cuts faster and with greater precision. It can process more food in the same amount of time, significantly increasing overall production capacity.

Adaptable

Whether it’s fresh pork, beef, or lamb bones, or frozen meat, fish, or even bone-in poultry, this machine can be used for multiple purposes, reducing investments in different equipment.

Labor Intensity

This bone saw eliminates the need for prolonged physical exertion, reducing worker fatigue and improving workplace safety.

Stability

The stainless steel body, coupled with a high-quality motor and blade system, ensures a long lifespan and stability even in demanding environments, reducing maintenance costs.

Costs

High cutting efficiency combined with a stable and durable structural design not only saves labor but also reduces the frequency of blade changes and repairs, thereby lowering long-term operating costs.

Scenarios

Whether it’s a medium- to large-scale slaughterhouse, a chain restaurant, a food processing workshop, or a cold chain cutting center, this commercial bone saw machine can efficiently meet your needs.

Bone Saw Usage Procedure

- Preparation and Inspection:Make sure the machine is properly mounted on a stable surface and connected to the power supply. Check the saw blade tension and guard for proper operation.

- Adjusting the Cut Size: Adjust the cutting distance and the position of the pressure plate according to the thickness of the food to be cut.

- Placing the Food: Place the meat or bone on the work surface, ensuring it is aligned with the cutting line.

- Starting the Machine: Press the start button, hold the food firmly, and slowly push the saw blade into position.

- Completing the Cut and Cleaning: After cutting, turn off the power supply and clean the work surface and blade to ensure the machine is clean.

FAQ

Yes. This machine is suitable for both fresh and frozen meat. Equipped with a high-power motor and high-speed saw blade, it can easily cut frozen meat and bones.

The stainless steel body has a smooth surface and is easy to disassemble and clean, meeting food processing hygiene requirements.

The unit’s dimensions are 630 × 560 × 1070 mm, making it a compact design ideal for small to medium-sized kitchens or meat processing facilities.

Why Choose Foodline Machinery

- Years of Industry Experience: With 20 years of experience specializing in machinery manufacturing and sales, we have a deep understanding of diverse customer needs.

- High-Quality Production Standards: All products are made of high-quality materials and precision-crafted, and undergo rigorous factory inspection.

- Global Export and Service: Our products are exported to numerous countries and regions, and we provide comprehensive after-sales technical support and spare parts.

- Customized Solutions: We offer meat and bone saw machines with various cutting sizes, power output, and appearance configurations to meet your specific needs.

Besides this model, we also have other models of bone sawing machines. Welcome to get a quote! WhatsApp/Phone: +86 13838385752.