Miguel Santos, a fruit processing business owner from Cebu City, Philippines, contacted our company. He runs a fruit and vegetable processing plant that supplies fresh processed fruit to supermarkets, juice chains, and exporters. While local pineapple production in the Philippines has continued to grow in recent years, manual peeling is inefficient, costly, and results in inconsistent finished product appearance. This prompted Miguel to seek a more efficient solution.

After comparing several equipment suppliers, he ultimately chose our automatic pineapple peeling machine. After the equipment was installed and commissioned, Miguel said:

“This machine not only tripled my production line speed but also reduced material waste. It’s easy to operate and clean, making it the most satisfying investment I’ve made in recent years.” Currently, the machine is operating stably in Miguel’s factory, helping him secure new export orders and further expanding his competitive advantage in the local market.

Pineapple Peeling Machine Parameter

| Parameter | Value |

|---|---|

| Capacity | 500 pcs/hour |

| Peeling Thickness | Adjustable 1.5–15mm |

| Fruit Height Range | 80–400mm |

| Fruit Diameter Range | 80–220mm |

| Coring Diameter | Customizable 16–30mm |

| Power | 1.5kW (220V, 50Hz) |

| Weight | 400kg |

| Dimensions (L×W×H) | 2450×900×1700mm |

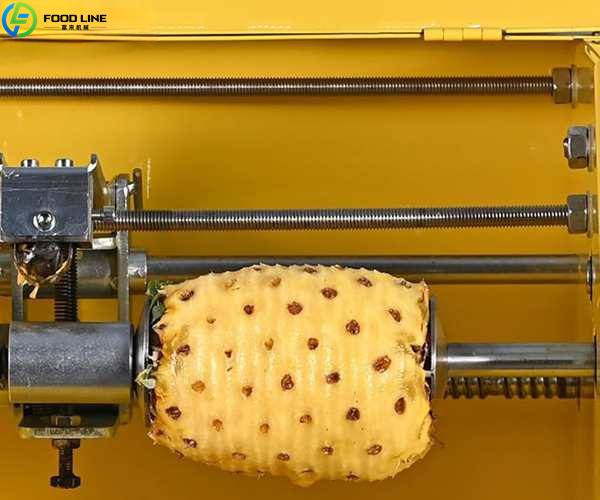

Automatic Pineapple Peeling Machine Product Features

- Fully Automatic Peeling System: The equipment automatically feeds, positions, and peels pineapples quickly, requiring no manual intervention and ensuring consistent cutting thickness.

- Intelligent Size Recognition: Equipped with an infrared or laser sensing system, it automatically identifies pineapple size and adjusts the blade position to maximize pulp retention and minimize waste.

- High-Strength Blades: The blades are made of food-grade stainless steel. Precision-ground and hardened, they are corrosion-resistant and wear-resistant, ensuring sharp cutting edges and a long service life.

- Energy-Efficient Design: The motor and drive system are optimized to maintain high efficiency while reducing energy consumption, meeting environmental and energy conservation requirements.

- Easy-to-clean structure: The machine features an open frame and quick-release blades, making daily cleaning and maintenance easier.

Advantages of Pineapple Peeling Machines

- Significantly Improved Efficiency: Compared to manual peeling, this system improves efficiency and significantly shortens delivery cycles, especially during peak season.

- Reduced Labor Costs: Reduced reliance on skilled labor reduces employment risks and training costs, and reduces losses due to human error.

- Stable Cutting Quality: Peeled pineapples are uniformly thick and beautifully shaped, making them suitable for direct packaging or further processing.

- High Durability: Core components are designed for a long lifespan, maintaining stable performance even in the high humidity and temperature conditions of the Philippines.

Overview of the Automatic Pineapple Peeler Market in the Philippines

The Philippines is one of the world’s leading pineapple producers, boasting extensive planting areas and high-quality pineapples. With growing demand for fresh-cut fruit, canned pineapples, and juice in both domestic and export markets. The demand for automated equipment in processing plants is increasing.

Currently, many small and medium-sized processing companies still rely on manual peeling. This is plagued by low efficiency, high costs, and poor product consistency. The introduction of an automatic pineapple peeling machine not only addresses these issues but also helps companies seize export market opportunities and enhance their competitiveness.

About Foodline Machinery

We are a professional manufacturer of food processing machinery, specializing in the design and manufacture of equipment for fruit and vegetable processing. Our products are widely exported to Southeast Asia, including the Philippines, Vietnam, Thailand, and Malaysia. With years of experience, we understand the needs of different markets. We also provide complete after-sales service, such as remote technical support, installation and commissioning, operator training, and spare parts supply. This guarantees the stable performance of our machines and gives customers peace of mind. Welcome to contact us for more information! WhatsApp/Phone: +86 13838385752.